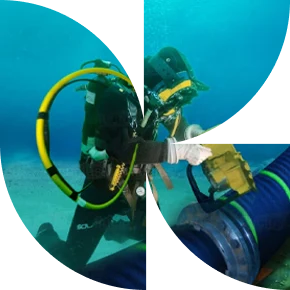

UNDER WATER INSPECTION

We conduct detailed underwater inspections using advanced techniques to assess conditions and detect potential issues.

- In-water class survey inspection.

- Underwater hull inspection with CCTV.

- Underwater port pillars inspection.

- Underwater marine structures inspection.

- Underwater clearance measurements.

- Underwater ultrasonic measurement.

- Underwater anodes testing.

In-water class survey inspection.

We carry out in-water class survey inspections in accordance with IACS and classification society standards. Our certified divers perform detailed examinations of the ship’s hull, appendages, and critical underwater components, providing full documentation to meet class renewal or intermediate survey requirements—often eliminating the need for dry-docking.

Underwater hull inspection with CCTV.

Our underwater hull inspection with CCTV provides real-time, high-resolution visual feedback to shipowners, managers, or classification surveyors. Using professional-grade underwater cameras operated by expert divers, we deliver detailed video evidence of the hull’s condition, fouling, and potential structural damage.

Underwater port pillars inspection.

We conduct structural integrity assessments of underwater port pillars and support systems. Our inspections evaluate corrosion, cracks, marine growth, and scour at the base of these critical structures, helping port authorities and engineers ensure long-term safety and stability.

Underwater marine structures inspection.

Our team inspects underwater components of jetties, piers, mooring dolphins, and other marine structures. Through visual, photographic, and video inspections, we assess structural condition, material degradation, and compliance with engineering standards, providing accurate reports and recommendations for maintenance or repair.

Underwater clearance measurements.

We perform precise underwater clearance measurements to determine the distance between a vessel’s keel and the seabed or berth. These measurements are essential for safe navigation in shallow waters, port operations, and when assessing grounding risks during berthing or unberthing.

Underwater ultrasonic measurement.

Using advanced underwater ultrasonic thickness measurement equipment, we assess the condition of submerged steel plating and structures. This non-destructive testing method provides accurate data on metal thickness, corrosion levels, and structural integrity, supporting preventative maintenance and compliance inspections.

Underwater anodes testing.

We carry out underwater testing of sacrificial anodes to evaluate their performance and remaining life. Our reports detail anode condition, coverage effectiveness, and recommend timely replacement to ensure continued cathodic protection of submerged hull and fittings.

Do You Have Questions About Our Underwater Inspection Services ?

Remote Operated Vehicles (ROVs), CCTV with divers, high-definition cameras, and ultrasonic testing devices are commonly used for accurate and safe inspections.

Data is collected via video, sonar, or sensor readings, then analyzed by engineers or software for anomalies. Findings are compiled in detailed reports including images, measurements, and recommendations.

Frequency depends on regulations and asset type. For example, offshore platforms and pipelines are typically inspected every 6 to 12 months, or after major weather events or incidents.

We are always ready to help you and answer your questions